Excitement and relief filled many South Africans on 23 August 2020 when President Cyril Ramaphosa announced our move to Level 2 of the national lockdown as part of the COVID-19 risk-adjusted strategy. Much of the exhilaration stemmed from the possibility of finally being able to visit family, go to parks and gyms, and also travel between provinces, among other things. This came at a time when the Mint is starting to operate and more colleagues are returning to work, bringing that spring spirit of new beginnings and renewed hope that the year could still end on a positive note.

COVID-19 restrictions don’t mean a lockdown on performance, as shown by our August recipients of the Cheers4Peers awards. Congratulations to Carolina Naudé (HR) for living the value of Service, and to Lunga Mokwena (IMS) for highlighting the values of Accountability and Service during these challenging times. Enjoy spending your R500 gift voucher!

Continue to give recognition where it is due, Minters! Nominate a colleague that you believe is doing a sterling job in living our values. By so doing, you are yourself setting an example of living our values.

While we celebrate the achievements of those who have done well at work this month, we are also inspired by the achievements of a colleague who, against all odds, received his qualification this month. Thomas Ngobeni shares an inspirational piece of how he, with the help and support of the people around him, overcame many obstacles to reach this commendable milestone in attaining a National Diploma in Law and an LLB degree.

Thomas Ngobeni with his qualifications.

Thomas Ngobeni and colleagues.

“Today by God’s grace, I am giving myself a birthday present. A birthday present which took me almost eight years to master and perfect. It was back in 2006, on this very same day on 18 August when I got a job to work as a delivery guy around the Pretoria CBD, earning R300 per week. I delivered furniture to people’s homes and the interactions I had and the things I saw inspired me.

That prompted me to go back and register for a matric certificate in 2007. The only school that was in a position to accommodate me was ABET in Soshanguve because I had left school in my Standard 6 year due to challenges I faced. For 10 years, I was at home chasing shadows, and I worked hard to pass with exemption that year. Seeing my name written in a newspaper for the class of 2007 was a feeling that I can never try to explain. When they say, ‘It runs in the family,’ you tell them, ‘This is where it runs out’.

In 2008 I got a job to work as a gardener and in 2010 I was employed by the South African Mint as a Plating Operator. The requirement of the job at the Mint was a matric certificate that I now hold. I then took my pay and went to UNISA to register for a Diploma in Law and I have never looked back since. There were many obstacles that I faced during my studies and many opportunities were there for me to give up because it was not comfortable to take almost all of your salary and pay for your studies and prescribed books. But I understood the quote that says: ‘Progress is impossible without change, and those who cannot change their minds cannot change anything’. I realised that I have a great passion for change and I was willing to hold on, no matter how uncomfortable the process was. By doing exactly that, I am today a proud holder of a National Diploma in Law and an LLB degree.

Thank you to all who contributed to my life, be it directly or indirectly. As I began to understand the psychological impact of the African proverb ‘It takes a village to raise a child’. I saw that in my life personally. A number of people contributed to my life and journey immensely and I will forever be grateful to them. To my wife who was there when I had no shoes to wear, to Thomas Mkasi who gave me his shoes to wear, to my foreman at the South African Mint, Mr Matlou, and my shift colleagues who were there for me in a number of ways. Thank you to my company, the South African Mint, for the study loan you gave me and the encouragement I got from you guys. I love you with all of my heart.

South African Mint, I WILL FLY YOUR FLAG HIGHER!” – Thomas Ngobeni, Plating Operator (Plating)

We strive to create change in our immediate communities by executing Corporate Social Investment (CSI) initiatives that are aligned with our core value of being a responsible and involved corporate citizen. The South African Mint’s support of the Imbumba Foundation’s Caring4 Girls initiative ensures that the young ladies at the Olievenhoutbosch Secondary School and Thembinkosi Special Needs School don’t miss a single day of school because of the lack of sanitary pads.

To celebrate Mandela day, all the girls at Thembinkosi received their supply of sanitary pads and on the 30th of August, as part of our Women’s month celebrations, we delivered a supply of sanitary pads to all the girls of Olievenhoutbosch Secondary School.

Learners from Olievenhoutbosch Secondary School and Thembinkosi Special Needs School with their sanitary towels from the South African Mint (archive photos due to lockdown).

INTELLIGENCE CENTRE ACT

We as the South African Mint constantly strive to better ourselves and the service to our customers and stakeholders. After we were recently audited with regard to the Financial Intelligence Centre Act 38 of 2001 (FICA or FIC Act), we implemented various improvements to processes and policies to ensure full compliance.

In terms of the FIC Act, the South African Mint and all our Authorised Dealers qualify as a reporting institution, and we have an obligation to report transactions as they relate to the FIC Act. To the extent that the FIC Act also addresses our Authorised Dealers, we have put the following measures in place to raise awareness on this issue:

– The banner below was added to the Authorised Dealer page on our website:

(https://www.samint.co.za/collectable-coins/authorised-dealers/)

INTELLIGENCE CENTRE ACT

We as the South African Mint constantly strive to better ourselves and the service to our customers and stakeholders. After we were recently audited with regard to the Financial Intelligence Centre Act 38 of 2001 (FICA or FIC Act), we implemented various improvements to processes and policies to ensure full compliance.

In terms of the FIC Act, the South African Mint and all our Authorised Dealers qualify as a reporting institution, and we have an obligation to report transactions as they relate to the FIC Act. To the extent that the FIC Act also addresses our Authorised Dealers, we have put the following measures in place to raise awareness on this issue:

– The banner below was added to the Authorised Dealer page on our website:

(https://www.samint.co.za/collectable-coins/authorised-dealers/)

– The following clause has been included in all dealer agreements since 2017:

“Despite the generality of clause 24.1, the Coin Dealer undertakes to comply particularly with domestic laws applicable to currency and counterfeit currency, exchange control, consumer protection, advertising and marketing, data protection, anti-money laundering, intellectual property, tax, insolvency, as well as anti-trust.

The Coin Dealer warrants, represents and undertakes to the Mint that, as at the Signature Date it is, and shall for the duration of this Agreement, and shall ensure that its personnel (where relevant) shall:

• always comply with applicable legislative requirements, which may include, but are not limited to:

• FICA Requirements and the reporting obligations related thereto;

• KYC principles set out in the FIC Act and obligations related thereto (to the extent that you are an accountable institution as contemplated in the FIC Act).

The Coin Dealer acknowledges that, to the extent that it deals in Krugerrand coins, it is a ‘reporting institution’ as contemplated in schedule 3 of the FIC Act and hereby undertakes to comply with the obligations applicable to reporting institutions as required by the FIC Act”.

– FICA Refresher Training for all the authorised dealers was held on 26 August 2020 by the South African Reserve Bank’s Risk Management team:

Thank you to all the people who continue to develop and improve our processes and policies to standards accepted by legistration such as the FIC Act.

We have journeyed together through the history of the South African currency, and seen how our colleagues work to bring design to life, now we’d like to show you how we get from metal to money when making a collectable coin.

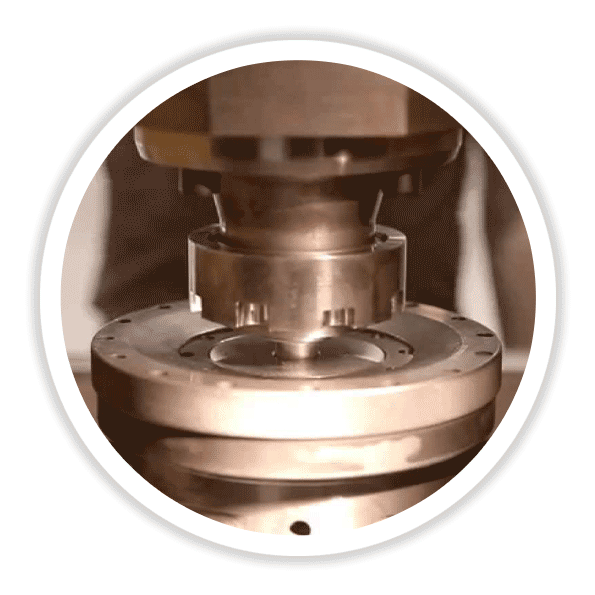

Production starts at the highly modern continuous casting furnace, where the raw materials are melted and then cast through casting dies manufactured from very high-grade graphite. There are separate casting dies for 22ct gold, 24ct gold and silver.

The gold that is melted in the crucible is activated by a starter bar which is placed in the die, to which the liquid gold attaches and thus initiates the casting process.

As soon as the correct temperature is reached, the starter bar is withdrawn from the die very slowly, and as it is pulled out, the molten gold flows into the die and solidifies. The metal comes out in one thickness and is then rolled down, the result of which is a drawn bar.

After the casting process, the drawn bar is washed and then rolled on a rolling mill to the correct thickness for the coin that is being minted. On the mill, the drawn bar is passed between two rollers to form a strip. The strip length increases as the thickness decreases.

Two operators control this process manually, one placing the strip into the mill and the other removing the strip from the mill. This is done with extreme care to prevent surface contamination as well as to avoid scratches to the strip surface.

Once the correct thickness is achieved, the strip is washed and inspected for any surface errors. After inspection, the strip is ready to be blanked.

During the blanking process, a blanking machine which is fitted with a punch and a cutter according to the specific diameter required, is operated manually by an operator. It is again very important that the strip be handled with extreme care so that the surface is not scratched and it can yield the maximum number of blanks possible.

Once the blanks are cut, they are individually inspected, checking their weight, diameter and visual acceptance according to the requirements of the coin to be minted.

Only 22ct gold and silver blanks go through this stage, which uses an open-ended steel belt furnace, equipped with heating and cooling zones that are protected by a continuous flow of gas, called an annealing furnace. The coin blanks are placed in the annealing furnace to soften them (relieve stress).

After softening, the blanks are placed in a heated acid and water solution for 5 to 10 minutes to eliminate any surface contamination, and their hardness is tested. Thereafter, the blanks are ready to be polished.

The surface of each blank is polished to a very high lustre to obtain an exceptional surface finish. The blanks are loaded into the polishing tub with special polishing compound and polishing media made of minute stainless steel balls of different shapes. The blanks will then be separated from the polishing media after the polishing process has been completed. The blanks will be loaded onto the special drier with a heat plate and special cloths.

If they pass the inspection, they are individually packed in a special tray. They are now ready for the coining process.

In the coining process, the blank is struck with two dies simultaneously, one for the obverse coin face and the other for the reverse coin face. The coining operator individually selects each blank, and feeds it into the coining press, which contains multi-stroke 200 – 260 ton knuckle presses, and a serrated collar that restricts the sideways flow of the material.

Each blank is struck between three and five times, depending on the diameter and detail of the coin being minted. After the coin is struck, the operator removes it and inspects it under a magnifying glass before placing it on a special storage tray.

Some coins are also placed in capsules at this stage. The dies are cleaned with a special soft cloth to remove any residue from the die faces first before the next blank can be struck. The coins are now ready to be packed according to specific packaging requirements.

Did you know? Circulation coins are struck only once, under normal pressure and at a high speed rate – as they need to be produced in large quantities and in accordance with the demands of a country. Collectable coins, in contrast, are usually struck at least twice, under high pressure, in order to bring out all the details in the design, as they draw their charm from the immaculate representation of the design as well as the limited quantities they come in.

Packing is the last phase before a coin is ready to be sold. Also a manual process, packers begin by conducting a final inspection of the coins.

The approved coins are then placed in different packaging created to compliment the coin theme and appeal to collectors. Some are even accompanied by adding items in the packaging such as medallions or miniature models.

According to the Britannica Kids encyclopedia, manufacturing is the process of making products, or goods, and the businesses that make products and goods are called manufacturers. Why not turn your young engineers into manufacturers with this fun activity to make a coin bank? Simply download, print and watch them have fun ‘manufacturing’ their own product!

Click here to download the coin bank activity.

You’ve heard the terms bullion, proof, uncirculated, or circulating coin, but do you know what they mean? Do you know the difference between them? Next month we’d like to give you a brief collector’s guide to striking standards…